Sale Injection Molded Plastic Pallets Factory Producer Company

In today's fast-paced world of logistics and supply chain management, the choice of pallets plays a crucial role in ensuring efficiency, durability, and sustainability. Among the myriad options available, injection molded plastic pallets have emerged as a preferred choice for many industries. This article explores the reasons behind the growing popularity of injection molded plastic pallets over traditional wood pallets and other alternatives.

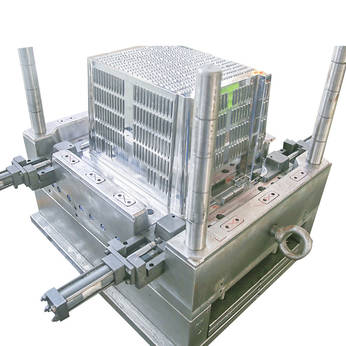

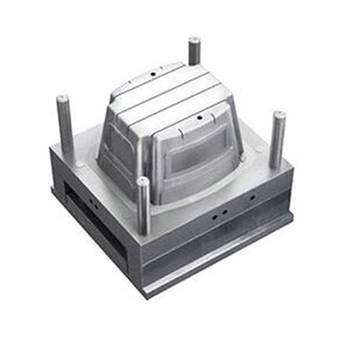

Injection molded plastic pallets are engineered using advanced manufacturing techniques that involve injecting molten plastic into a mold cavity. This process allows for precise customization, enabling the production of pallets tailored to specific load requirements and handling conditions. Unlike wood pallets, which are susceptible to moisture, pests, and damage, injection molded plastic pallets offer predominant durability and resistance to environmental factors.

One of the key advantages of injection molded plastic pallets is their consistent quality and dimensional accuracy. Unlike wood pallets, which may vary in size and shape due to natural inconsistencies in the material, injection molded plastic pallets are manufactured to precise specifications, ensuring compatibility with automated handling systems and storage racks. This consistency translates into improved efficiency and reduced downtime in warehouse operations.

Moreover, injection molded plastic pallets are lightweight yet robust, making them easier to handle and transport compared to their wooden counterparts. This lightweight design not only reduces shipping costs but also small the risk of worker injuries associated with lifting heavy pallets. Additionally, the smooth, non-porous surface of injection molded plastic pallets is easier to clean and sanitize, making them ideal for industries with stringent hygiene requirements, such as food and pharmaceuticals.

In recent years, sustainability has become a major driving force behind the adoption of injection molded plastic pallets. Unlike wood pallets, which are often sourced from virgin timber and contribute to deforestation, injection molded plastic pallets are typically made from recycled or recyclable materials. This eco-friendly approach not only reduces the carbon footprint of pallet manufacturing but also helps companies meet their sustainability goals and comply with environmental regulations.

Furthermore, injection molded plastic pallets offer a higher return on investment over their lifespan compared to wood pallets. While the initial cost of plastic pallets may be higher, their durability and longevity result in lower total cost of ownership and fewer replacements over time. This cost-effectiveness, combined with the other benefits mentioned, makes injection molded plastic pallets a compelling choice for companies seeking to optimize their supply chain operations.

In conclusion, injection molded plastic pallets are gaining popularity across industries due to their numerous advantages over traditional wood pallets. Their predominant durability, customization options, lightweight design, and environmental sustainability make them a preferred choice for modern logistics and warehousing applications. As companies continue to prioritize efficiency, safety, and sustainability in their operations, the demand for injection molded plastic pallets is expected to rise steadily in the years to come.

Throughout this article, we have highlighted the importance and benefits of injection molded plastic pallets in modern logistics and supply chain management. These pallets offer numerous advantages over traditional wood pallets, including predominant durability, customization options, lightweight design, and environmental sustainability. As companies seek to optimize their operations and reduce costs, injection molded plastic pallets have emerged as a preferred choice for their efficiency, safety, and sustainability.

English

English русский

русский

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)