Advantages Of Household Plastic Injection Mold

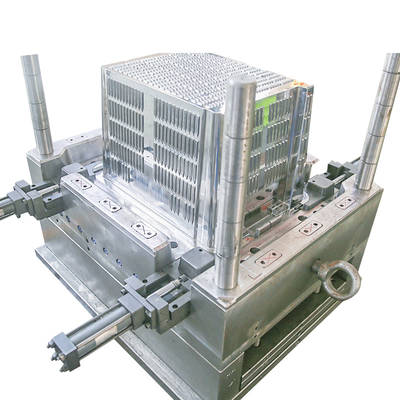

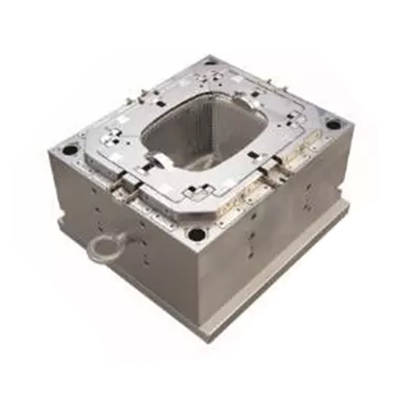

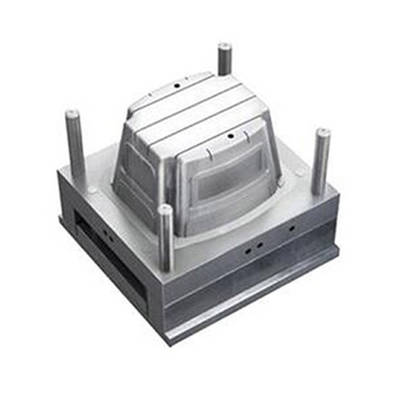

Household plastic injection molds are used to create a wide range of plastic parts and components for use in household products. The advantages of using household plastic injection molds include:

1. High precision: Plastic injection molds are designed to create parts with high accuracy and precision. The molds are made from high-quality materials, such as steel or aluminum, which allow for precise shaping of the plastic.

2. Durability: Plastic injection molds are built to withstand the high pressures and temperatures involved in the injection molding process. They are made from materials that are strong and durable, allowing them to withstand the repeated use required in high-volume manufacturing.

3. Versatility: Plastic injection molds can be used to create a wide range of plastic parts and components for use in household products. This includes everything from kitchen utensils to electronic devices and toys.

4. Cost-effective: Plastic injection molding is a cost-effective solution for high-volume production of plastic parts. The molds can be used to create large quantities of parts with minimal waste, making the injection molding process an efficient and cost-effective method of manufacturing.

5. Design flexibility: Plastic injection molds offer design flexibility, allowing for the creation of complex shapes and designs that cannot be created using other manufacturing processes. This allows for the production of parts with intricate designs and shapes that the are both functionally and aes

The advantages of household plastic injection molds make them a valuable tool in the manufacturing process. They allow for the efficient production of plastic parts and components with high precision and accuracy, while also being cost-effective and versatile.

Trends In Household Plastic Injection Mold

Customization: Consumers are increasingly looking for products that are customized to their specific needs and preferences. This trend is driving the demand for household plastic injection molds that can create customized products quickly and efficiently.

Sustainability: Environmental concerns are driving the demand for sustainable and eco-friendly products. Household plastic injection molds are being developed that use recycled materials or biodegradable plastics to reduce waste and environmental impact.

Automation: The use of automation in household plastic injection molding is increasing, with more manufacturers investing in robotic systems and automated equipment. This trend is driving increased efficiency and productivity, as well as reducing labor costs.

Miniaturization: Many household products are becoming smaller and more compact, which is driving the demand for smaller and more precise plastic injection molds. This trend is particularly prevalent in the electronics industry, where small and precise components are in high demand.

Digitalization: The use of digital technologies, such as 3D printing and computer-aided design (CAD), is increasing in the household plastic injection molding industry. These technologies allow for faster and more efficient product development, as well as greater design flexibility.

These trends in household plastic injection mold manufacturing are driving innovation and change in the industry. Manufacturers that are able to adapt to these trends and incorporate them into their operations are likely to be more successful in meeting the evolving needs of consumers and et staying.

Industry Standard For Household Plastic Injection Mold

There are several industry standards for

household plastic injection molds that manufacturers should be aware of. These standards help to ensure that the molds are safe, reliable, and of high quality. Some of the key industry standards include:

1. ISO 9001: This standard specifies requirements for a quality management system, including the design, development, production, and servicing of plastic injection molds. ISO 9001 certification indicates that a manufacturer has implemented an effective quality management system.

2. ASTM D4169: This standard provides a series of test methods for evaluating the performance of shipping containers and systems, including plastic injection molds. Manufacturers can use these test methods to ensure that their molds are able to withstand the rigors of transportation and shipping.

3. UL 746A: This standard provides guidelines for the testing and certification of plastic materials for use in electrical and electronic equipment. Manufacturers can use UL 746A certification to demonstrate that their plastic injection molds meet the necessary safety requirements for use in these licenses.

4. RoHS: The Restriction of Hazardous Substances (RoHS) Directive restricts the use of certain hazardous substances, such as lead and mercury, in electrical and electronic equipment. Manufacturers can ensure compliance with RoHS requirements by using plastic injection molds that are certified as RoHS compliant.

5. FDA: The U.S. Food and Drug Administration (FDA) regulates the use of plastic materials in contact with food. Manufacturers can ensure compliance with FDA regulations by using plastic injection molds that are certified as food grade or that meet FDA requirements for food contact .

English

English русский

русский

.jpg?imageView2/2/w/400/format/jp2/q/70)

.jpg?imageView2/2/w/400/format/jp2/q/70)

.jpg?imageView2/2/w/400/format/jp2/q/70)