Design High Quality Injection Molded Plastic Pallets Supplier

In today's fast-paced industrial landscape, the demand for efficient and adaptable logistics solutions has never been higher. Among the myriad options available, injection molded plastic pallets stand out as versatile, durable, and customizable tools for material handling and storage. In this article, we delve into the realm of customization and design, exploring how injection molded plastic pallets can be tailored to suit the specific needs of various industries.

Injection molded plastic pallets offer a plethora of benefits over traditional wooden pallets or other materials. Their inherent strength, resistance to moisture and pests, and consistent dimensions make them ideal for a wide range of applications, from food and beverage to pharmaceuticals and automotive manufacturing. However, what truly sets injection molded plastic pallets apart is their customizability.

When it comes to customization, injection molded plastic pallets offer unparalleled flexibility. From size and shape to color and load capacity, these pallets can be tailored to meet the unique requirements of any operation. Need a pallet with reinforced corners for added durability? No problem. Require a specific color for easy identification in a crowded warehouse? Consider it done. The ability to customize injection molded plastic pallets ensures that they seamlessly integrate into existing workflows, optimizing efficiency and streamlining processes.

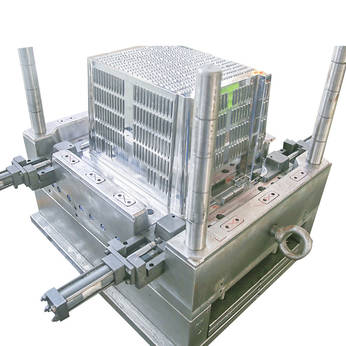

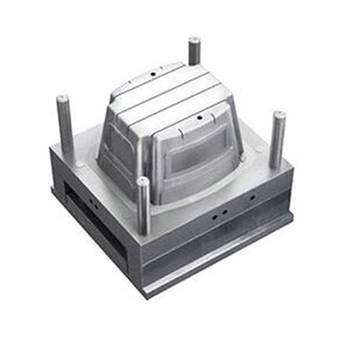

Moreover, the design possibilities afforded by injection molding technology are virtually limitless. Unlike traditional manufacturing methods, which may be limited by the constraints of wood or metal, injection molding allows for intricate designs and complex geometries. This means that injection molded plastic pallets can be engineered with features such as nesting capabilities for space-saving storage, integrated RFID tags for tracking and inventory management, or specialized surface textures for enhanced grip and stability.

In addition to their functional benefits, customization and design play a crucial role in enhancing brand identity and visibility. By imprinting logos or branding elements directly onto the pallets, companies can effectively promote their products and services throughout the supply chain. Whether in transit, on the warehouse floor, or at the point of sale, injection molded plastic pallets serve as tangible ambassadors for brands, reinforcing their presence and leaving a lasting impression on customers and partners alike.

Furthermore, the ability to customize injection molded plastic pallets extends beyond mere aesthetics. By tailoring pallet designs to specific applications or industries, companies can achieve significant cost savings and operational efficiencies. For example, a pharmaceutical manufacturer may require pallets with smooth surfaces and rounded edges to facilitate easy cleaning and prevent contamination. Conversely, an automotive assembly plant may prioritize pallets with integrated drainage channels to prevent water buildup and corrosion. By understanding and addressing these unique requirements, injection molded plastic pallets can deliver tangible value throughout the supply chain.

In conclusion, customization and design are integral aspects of injection molded plastic pallets that set them apart as indispensable tools for modern logistics and material handling. With their unmatched versatility, durability, and adaptability, injection molded plastic pallets offer a tailored solution to the diverse needs of today's industries. By harnessing the power of customization, businesses can unlock new opportunities for efficiency, innovation, and growth, ensuring that their operations remain agile and competitive in an ever-evolving marketplace.

English

English русский

русский

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)