In the realm of modern transportation and logistics, the demand for robust and reliable solutions has never been more crucial. One such innovation making waves is the Thick Durable Plastic Turnover Box, crafted through meticulous Injection Moulding processes. These containers, designed for the seamless transportation of goods, have become an indispensable asset in various industries.

The primary feature that sets these turnover boxes apart is their thickness and durability. Constructed from high-quality plastic materials, these containers boast a robust structure that ensures the safe handling and transit of diverse goods. The injection molding technique employed in their production imparts a level of precision and consistency that is paramount in meeting the stringent standards of logistics operations.

The significance of these turnover boxes becomes evident in their diverse applications across supply chains. From the automotive sector, where delicate components need secure transportation, to the pharmaceutical industry, where the integrity of medicines is of utmore importance, these plastic containers provide a versatile solution. The thickness of the material ensures that the contents are shielded from external forces during transit, fewer the risk of damage.

Moreover, the durability of these boxes extends their lifespan, making them a sustainable and cost-effective choice for businesses aiming to reduce their environmental footprint. The longevity of these containers not only contributes to waste reduction but also aligns with the growing emphasis on eco-friendly practices in the corporate world.

In the context of globalization, where goods traverse vast distances before reaching their destinations, the Thick Durable Plastic Turnover Box plays a pivotal role in ensuring the integrity of the supply chain. Its resilience to wear and tear, coupled with the ability to withstand varying climatic conditions, makes it an ideal choice for international shipping.

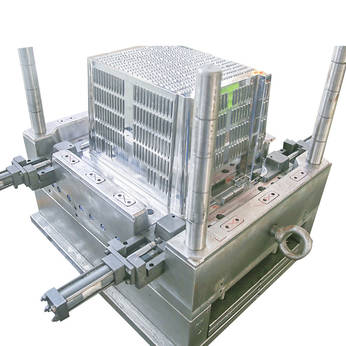

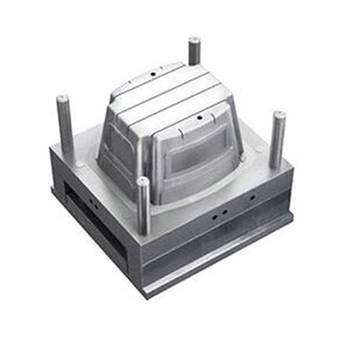

The injection molding process, utilized in the creation of these turnover boxes, involves injecting molten plastic into a mold cavity, creating a uniform and seamless product. This method not only ensures consistency in design but also allows for customization based on specific industry requirements. The result is a standardized yet adaptable solution that caters to the unique needs of different sectors.

In conclusion, the Thick Durable Plastic Turnover Box, born from the precision of injection molding, stands as a testament to innovation in the field of logistics. Its thick and durable construction addresses the core challenges of transportation, offering a reliable solution that safeguards the integrity of goods. As industries continue to evolve, these plastic containers serve as a beacon, guiding the way towards efficient and sustainable logistics practices.

The versatility of these containers extends beyond their durability. The injection molding process allows for intricate designs, optimizing storage space and facilitating ease of handling. This adaptability proves crucial in diverse industries, from automotive to food and pharmaceuticals, where the need for secure and organized transportation is paramount. Moreover, the Thick Durable Plastic Turnover Box promotes cost-effectiveness by minimizing damage to transported goods. Its resilience against external forces and harsh conditions ensures that products reach their destination in pristine condition, reducing financial losses associated with damaged inventory.

English

English русский

русский

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)