ODM Custom Injection Molded Plastic Pallets Manufacturing

In today's rapidly evolving logistics landscape, the demand for efficient, durable, and sustainable material handling solutions has never been higher. Among these solutions, injection molded plastic pallets have emerged as a game-changer, revolutionizing the way goods are transported and stored. This article delves into the innovative advancements of injection molded plastic pallets, exploring their rise to prominence in material handling industries worldwide.

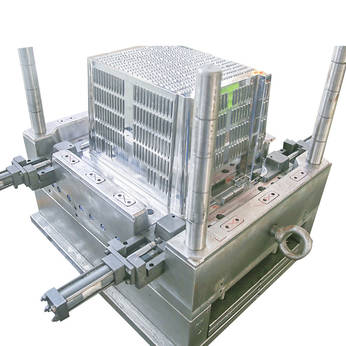

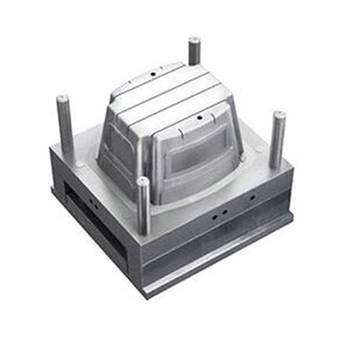

Injection molded plastic pallets represent a significant departure from traditional wooden or metal pallets. Manufactured through a process where molten plastic is injected into a mold and cooled to form a solid structure, these pallets offer numerous advantages over their counterparts. Their design allows for intricate configurations and customization options, catering to the diverse needs of various industries. Moreover, injection molded plastic pallets boast exceptional strength-to-weight ratios, providing robust support for heavy loads while remaining lightweight for ease of handling.

One of the key advantages of injection molded plastic pallets lies in their durability and longevity. Unlike wooden pallets, which are susceptible to moisture, pests, and wear, plastic pallets are resistant to these elements, ensuring consistent performance in diverse environments. This durability translates into cost savings for businesses, as injection molded plastic pallets have a significantly longer lifespan and require small maintenance compared to traditional alternatives.

Furthermore, injection molded plastic pallets contribute to sustainability efforts in material handling. Made from recycled or virgin plastic materials, these pallets are fully recyclable at the end of their lifecycle, reducing environmental impact and promoting circular economy practices. Additionally, their lightweight design facilitates fuel efficiency during transportation, further lowering carbon emissions and enhancing overall eco-friendliness.

The versatility of injection molded plastic pallets extends beyond their basic functionality. With advancements in design and manufacturing technologies, these pallets can be tailored to specific applications, such as food and pharmaceutical industries that require hygienic and FDA-compliant solutions. Additionally, features like anti-slip surfaces, nesting capabilities, and RFID tracking integration enhance operational efficiency and traceability in supply chain management.

As businesses increasingly prioritize safety and compliance in their operations, injection molded plastic pallets offer peace of mind. Their uniform construction eliminates protruding nails or splinters, reducing the risk of injuries during handling and transportation. Moreover, plastic pallets adhere to international standards and regulations governing pallet design and performance, ensuring compatibility with automated warehouse systems and safe handling practices.

The adoption of injection molded plastic pallets is not limited to a specific industry or geographical region. From manufacturing facilities to distribution centers, retail stores to agricultural operations, businesses across diverse sectors are embracing the benefits of these innovative material handling solutions. Their widespread acceptance underscores the transformative impact of injection molded plastic pallets on the efficiency, sustainability, and safety of global supply chains.

The evolution of material handling practices has witnessed a significant shift with the emergence of injection molded plastic pallets. These pallets, constructed through an intricate injection molding process, offer unparalleled durability, versatility, and sustainability. Unlike traditional wooden pallets, injection molded plastic pallets provide a robust solution for transporting goods across various industries.

One of the key advantages of injection molded plastic pallets is their ability to withstand bad conditions, including temperature variations, moisture, and chemical exposure. This resilience ensures the safe transportation of goods, even in challenging environments such as warehouses, distribution centers, and manufacturing facilities.

English

English русский

русский

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)