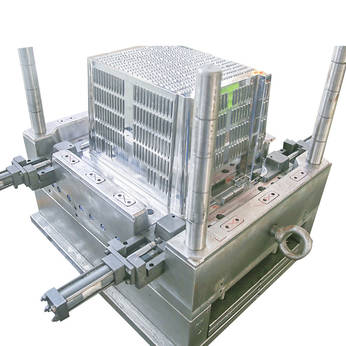

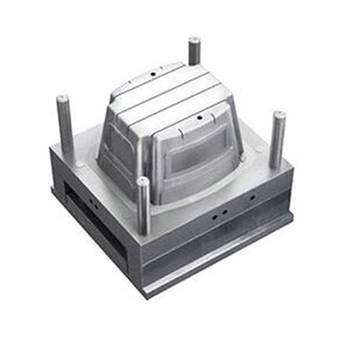

Huangyan, Taizhou, Zhejiang, is the hometown of civilized molds. With the development of the times and the advancement of technology, the injection mold process has become more mature. The process of injection molds involves many aspects. Today we will talk about the polishing of injection molds.

Mold polishing is a process that uses oilstone, sandpaper, polishing paste, wool wheel, etc. to polish the surface of the mold cavity so that the working surface of the mold can be as bright as a mirror. This is called mold polishing.

Injection mold process Injection mold polishing has two purposes; one is to increase the smoothness of the plastic mold so that the surface of the product produced by the plastic mold is smooth, beautiful and beautiful; the other is to make the plastic mold easy to demould so that the plastic will not be stuck to the plastic mold But can’t take it off, here are the injection molding manufacturers’ mold polishing precautions summarized this time:

1. When starting to process a new mold cavity, you should first check the surface of the workpiece and clean the surface with kerosene so that dirt will not stick to the oilstone surface and cause the cutting function to be lost.

2. When grinding coarse grains, grind them in the order of difficulty first and then easy grinding. Especially for some dead corners that are difficult to grind, the deeper bottoms should be grinded first.

3. Some workpieces may have multiple pieces assembled together for polishing. The rough lines or spark lines of individual workpieces must be ground separately first, and then all workpieces must be polished together until they are smooth.

4. For workpieces with large flat surfaces or side surfaces, use a whetstone to grind away the rough lines and then use a straight steel sheet for light transmission inspection to check whether there are any uneven or undercut problems. If there are undercuts, the finished product will be damaged. Difficulty in demoulding or the parts are strained.

5. In order to prevent the plastic mold workpiece from being undercut or having some fitting surfaces that need to be protected, you can paste it with a saw blade or stick it to the edge with sandpaper, so that you can get the ideal protection effect.

6. Pull the flat surface of the plastic mold back and forth, and drag the handle of the oil stone as flat as possible, not exceeding 25°. Because the slope is too large, the force rushes from top to bottom, which can easily lead to many rough lines on the workpiece.

7. Achieving a mirror-like finish on the mold surface requires a progressive approach. Start with a coarser grit and gradually move to finer abrasives to ensure a smooth, flawless surface.

8. Patience is key in mold polishing. Rushing through the process can result in uneven surfaces and compromise the quality of the final product.

9. It's crucial to maintain a clean working environment. Contaminants like dust or debris can ruin the precision of the polishing process, so regular cleaning is essential.

10. The use of specialized polishing compounds and lubricants can significantly enhance the efficiency of the polishing process. These aids reduce friction, prevent overheating, and ensure a more consistent finish.

11. Proper ventilation and safety precautions are vital when working with abrasive materials and polishing compounds to protect the health of the workers.

12. Throughout the polishing process, frequent inspections should be conducted to identify any irregularities or imperfections. Any issues should be addressed promptly to avoid defects in the final molded products.

13. Communication between mold designers, engineers, and the polishing team is essential. This ensures that the desired specifications and surface finishes are achieved, meeting both aesthetic and functional requirements.

14. Finally, regular maintenance of the polishing tools is important to maintain consistent quality in mold production. Dull or damaged tools can compromise the entire process.

Mold polishing is a skill-intensive process that plays a crucial role in producing high-quality plastic products. Careful attention to detail and adherence to these precautions can result in molds that produce smooth, beautiful, and defect-free products.

English

English русский

русский

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)