In the dynamic realm of automotive manufacturing, the integration of CNC (Computer Numerical Control) technology has revolutionized the production of car parts and plastic injection moulds. This synergy of advanced machinery and innovative techniques has ushered in a new era of precision engineering, transforming the landscape of the automotive industry.

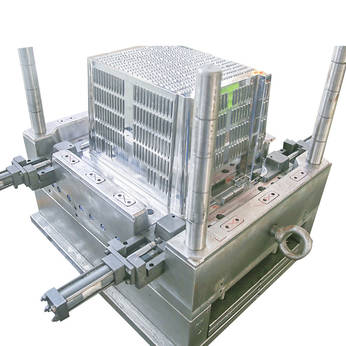

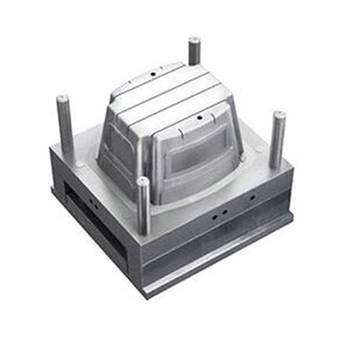

CNC technology plays a pivotal role in the fabrication of car parts, ensuring unparalleled accuracy and consistency. The intricate designs of modern vehicles demand a level of precision that traditional manufacturing processes struggle to achieve. With CNC Car Parts Auto Bumper Plastic Injection Mould, from engine components to intricate interior elements, can be produced with remarkable precision, meeting the stringent quality standards of today's automotive manufacturers.

Auto bumpers, a crucial safety component of vehicles, have also undergone a transformative evolution with the advent of CNC technology. The utilization of CNC machining in the production of auto bumper plastic injection moulds allows for the creation of complex and durable designs. These moulds enable the manufacturing of bumpers that not only provide impact resistance but also contribute to the overall aesthetics of the vehicle.

The precision offered by CNC machining in the production of auto bumper moulds translates into enhanced safety features. Vehicles equipped with bumpers crafted through CNC technology exhibit predominant crash performance, mitigating the impact of collisions and ensuring the safety of occupants. This has become increasingly important as automotive manufacturers strive to meet and exceed stringent safety regulations worldwide.

Furthermore, CNC machining brings efficiency to the manufacturing process, reducing lead times and enhancing overall productivity. The automation inherent in CNC technology allows for 24/7 operation, optimizing production schedules and fewer downtime. This efficiency not only benefits manufacturers in terms of cost-effectiveness but also ensures a steady supply of high-quality car parts and bumpers to meet the demands of the market.

The environmental impact of CNC technology in the production of car parts and auto bumper plastic injection moulds cannot be overlooked. The precision afforded by CNC machining results in less material waste, contributing to sustainability efforts within the automotive industry. Manufacturers can optimize material usage, reducing both costs and environmental footprint.

In conclusion, the marriage of CNC technology with the manufacturing of car parts and auto bumper plastic injection moulds marks a significant leap forward in the automotive industry. The precision, efficiency, and environmental sustainability brought about by CNC machining redefine the standards of modern manufacturing. As we continue to embrace technological advancements, the evolution of CNC car parts and auto bumper moulds stands as a testament to the industry's commitment to excellence and innovation.

English

English русский

русский

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)