All kinds of tools and products we use in our daily production and life, ranging from the base of the machine tool, the shell of the machine body, to the shell of a head screw, button and various household appliances, are all closely related to the mold. The shape of the mold determines the shape of these products, and the processing quality and precision of the mold also determine the quality of these products. Due to the different materials, appearance, specifications and uses of various products, molds are divided into non-plastic molds such as casting molds, forging molds, die-casting molds, stamping molds, and plastic molds.

In recent years, with the rapid development of the plastics industry and the continuous improvement of the strength and precision of general-purpose and engineering plastics, the application scope of plastic products is also expanding, such as: household appliances, instrumentation, construction equipment, automobile industry, daily In many fields such as hardware, the proportion of plastic products is increasing rapidly. A well-designed plastic part can often replace multiple traditional metal parts. The trend towards plasticization of industrial and daily products is on the rise.

1. General definition of mold: In industrial production, various presses and special tools installed on the press are used to make metal or non-metallic materials into parts or products of the desired shape through pressure. Such special tools are collectively referred to as molds. .

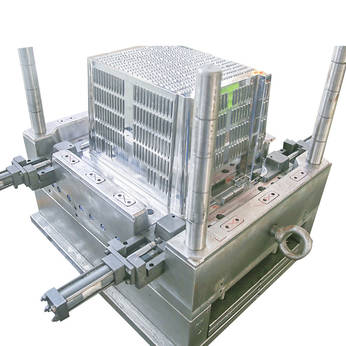

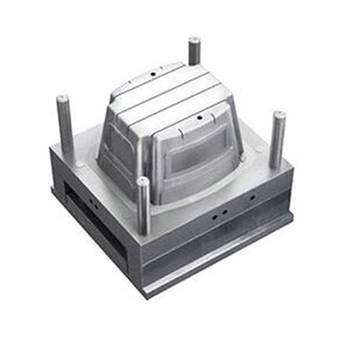

2. Description of the injection molding process: The mold is a tool for producing plastic products. It consists of several sets of component parts, which have forming cavities within this set. During injection molding, the mold is clamped on the injection molding machine, the molten plastic is injected into the molding cavity, and cooled and shaped in the cavity, and then the upper and lower molds are separated, and the product is ejected from the cavity through the ejection system to leave the mold, and finally the mold is closed again. For the next injection, the entire injection process is cyclic.

3. General classification of molds: It can be divided into plastic molds and non-plastic molds:

(1) Non-plastic molds include: casting molds, forging molds, stamping molds, die-casting molds, etc.

A. Foundry mold - faucet, pig iron platform B. Forging die - car body C. Stamping die - computer panel D. Die Casting Die - Super Alloy, Cylinder Block

(2) Plastic molds are divided into:

A. Injection molding mold - TV casing, keyboard buttons (the most common application) B. Blow mold - beverage bottle C. Compression molding molds - bakelite switches, scientific porcelain bowls and dishes D. Transfer molding mold - integrated circuit products E. Extrusion die - glue tube, plastic bag F. Thermoforming mold - transparent forming packaging shell G. Rotary forming mold - soft doll toy

The injection mold is composed of several steel plates with various parts, which are basically divided into:

A Forming device (die, punch) B Positioning device (guide post, guide bush) C Fixing device (I-shaped plate, code pit) D Cooling system (water hole) E Constant temperature system (heating pipe, heating wire) F runner system (nozzle hole, runner groove, runner hole) G ejector system (thimble, ejector stick)

4. Hot runner system, also known as hot runner system, is mainly composed of hot sprue sleeve, hot runner plate and temperature control electric box. Our common hot runner system has two types of single-point hot gate and multi-point hot gate. The single-point hot gate uses a single hot gate sleeve to directly inject the molten plastic into the cavity, which is suitable for plastic molds with a single cavity and a single gate; Divided into the heat sprue sleeve and then into the cavity, it is suitable for single-cavity multi-point feeding or multi-cavity molds.

Advantages of Hot Runner Systems

(1) No water mouth material, no post-processing is required, the entire molding process is fully automated, working time is saved, and work efficiency is improved.

(2) The pressure loss is small. The temperature of the hot runner is equal to the nozzle temperature of the injection molding machine, which avoids the condensation of the raw material on the surface of the runner, and the injection pressure loss is small.

(3) The repeated use of the nozzle material will degrade the plastic performance, and the use of the hot runner system without the nozzle material can reduce the loss of raw materials, thereby reducing the cost of the product. The temperature and pressure in the cavity are uniform, the stress of the plastic part is small, and the density is uniform. Under the smaller injection pressure and the shorter molding time, the injection molding system can produce better products than the general injection molding system. For transparent parts, thin parts, large plastic parts or high-demand plastic parts, it can show its advantages, and it can produce larger products with smaller models.

(4) The hot nozzle adopts standardized and serialized design, equipped with various optional nozzle heads, and has good interchangeability. The uniquely designed and processed electric heating ring can achieve uniform heating temperature and long service life. The hot runner system is equipped with hot runner plates, thermostats, etc., with exquisite design, various types, easy to use, and stable and reliable quality.

English

English русский

русский

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)